Supply Chain Planning Steps

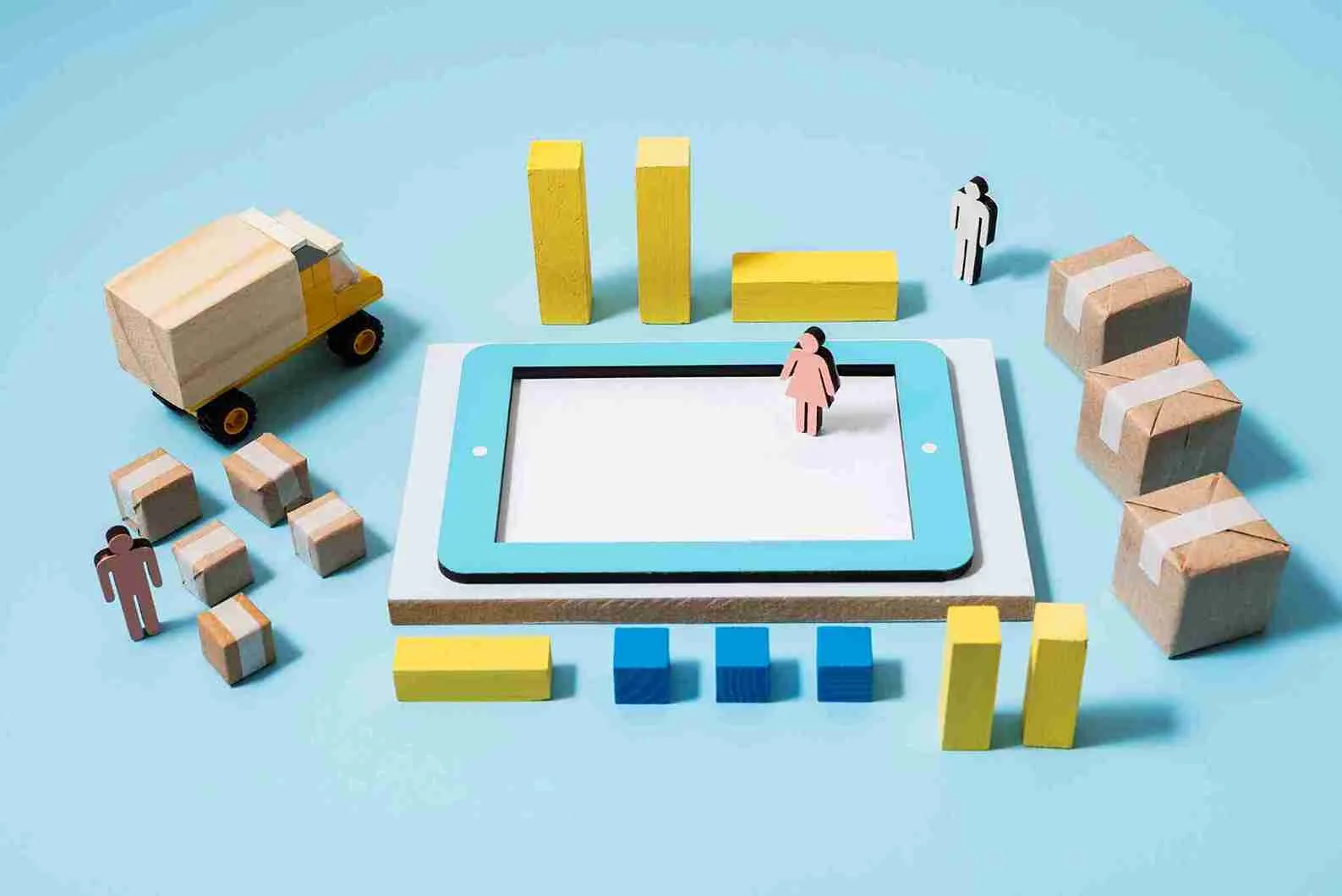

Imagine a business where products never arrive late, shelves are always stocked, and customer demand is met with precision. Behind this seamless flow lies one crucial engine: supply chain planning. Far more than just logistics, supply chain planning is the strategic backbone that helps businesses anticipate needs, allocate resources, and respond swiftly to market shifts.

But mastering this process doesn’t happen by chance—it requires a clear, step-by-step approach. Whether you’re scaling operations or refining your current workflow, understanding the essential steps of supply chain planning can mean the difference between growth and chaos.

1. Demand Planning

Objective: Forecast customer demand to ensure that supply aligns with actual market needs.

Demand planning is the cornerstone of any supply chain strategy. It involves analyzing historical sales data, market trends, seasonal patterns, and customer behavior to create accurate forecasts. This process is vital for making informed decisions about purchasing, inventory, and production.

A successful demand plan minimizes excess inventory, prevents stockouts, and helps companies respond quickly to market shifts. Modern demand planning often incorporates AI and machine learning tools to analyze vast datasets and identify patterns that human analysts might overlook.

Key Activities:

- Reviewing historical sales and trends

- Collaborating with sales and marketing teams

- Incorporating external market data and promotional schedules

- Adjusting for new product launches and discontinuations

2. Supply Planning

Objective: Determine how best to meet forecasted demand with available resources and constraints.

Once demand is projected, supply planning comes into play. This step focuses on how your company will fulfill that demand, considering inventory levels, supplier lead times, procurement capabilities, production capacity, and cost factors. The supply chain management process ensures that products are available when and where they are needed—without overproducing or overspending.

Supply planning also requires regular coordination with vendors, manufacturers, and logistics providers. A lack of alignment here can result in service failures, missed sales opportunities, or increased operational costs.

Key Components:

- Procurement planning

- Supplier capacity analysis

- Multi-echelon inventory optimization

- Risk mitigation strategies (e.g., dual sourcing, buffer stock)

3. Production Planning

Objective: Develop an executable plan to produce the right products at the right time and quantity.

Production planning is where the rubber meets the road in supply chain operations. It involves converting supply plans into a detailed schedule for manufacturing. This includes deciding what products to produce, when to produce them, and how much of each to make based on resource availability and forecasted demand.

It’s essential to coordinate closely with operations, procurement, and quality assurance teams. Inefficiencies in production planning can lead to bottlenecks, machine downtime, overproduction, or product shortages—all of which negatively impact customer satisfaction and profitability.

Key Considerations:

- Machine and labor availability

- Bill of materials (BOM) and routing plans

- Maintenance schedules

- Yield and scrap rates

4. Inventory Planning

Objective: Optimize inventory levels to ensure product availability while minimizing holding costs.

Effective inventory planning strikes a delicate balance between having enough stock to meet customer needs and not tying up capital in excess or obsolete inventory. It includes setting reorder points, safety stock levels, and planning for lead times and demand variability.

Poor inventory management can lead to overstocking (resulting in waste or markdowns) or stockouts (leading to lost sales and customer dissatisfaction). A robust inventory strategy improves working capital, streamlines operations, and supports better service levels.

Key Techniques:

- Economic order quantity (EOQ)

- Just-in-time (JIT) inventory

- ABC inventory classification

- Demand-driven replenishment

5. Logistics and Distribution Planning

Objective: Efficiently manage the movement of goods from origin to destination.

Logistics and distribution planning ensures that products get to customers or retail locations in a timely and cost-effective manner. It includes route optimization, freight selection, warehousing decisions, and distribution channel strategy. In an omnichannel environment, this step becomes increasingly complex, requiring real-time visibility and coordination.

Companies must also consider last-mile delivery challenges, return logistics, and sustainability goals. Advanced logistics planning tools use real-time data and AI to improve transportation efficiency and reduce environmental impact.

Key Components:

- Transportation management systems (TMS)

- Carrier selection and rate negotiation

- Distribution center (DC) placement and capacity planning

- Customs and compliance for international shipments

6. Sales and Operations Planning (S&OP)

Objective: Align supply chain plans with broader business strategies and financial goals.

Sales and Operations Planning is a collaborative process that bridges the gap between different functions—sales, marketing, finance, operations, and supply chain. It ensures everyone is working from a single plan that supports both customer service objectives and profitability.

S&OP typically involves monthly cycles where teams review performance, adjust forecasts, resolve conflicts, and make trade-offs. It creates a forum for informed decision-making and long-term alignment.

Key Elements:

- Demand and supply reconciliation

- Scenario planning and trade-off analysis

- Executive decision-making and sign-off

- Integration with financial planning and budgeting

7. Monitoring, Analytics, and Continuous Improvement

Objective: Track performance metrics and adapt plans to improve over time.

Supply chain planning is not a one-and-done activity—it requires continuous monitoring and refinement. This involves tracking key performance indicators (KPIs), analyzing deviations, and making data-driven improvements to planning processes.

With real-time dashboards and predictive analytics in a supply chain management solution, companies can proactively manage disruptions, optimize performance, and fine-tune operations. This culture of continuous improvement builds a more resilient and responsive supply chain over time.

Common KPIs:

- Order fulfillment rate

- Inventory turnover ratio

- Forecast accuracy (MAPE)

- Customer service level

- Supply chain cycle time

Final Thoughts

Supply chain planning is a dynamic, multi-step process that forms the backbone of any successful business operation. Each step—from demand forecasting to continuous improvement—plays a critical role in building a supply chain that is responsive, efficient, and customer-focused.

By mastering these steps and leveraging the right tools and collaboration, companies can not only mitigate risk but also unlock new growth opportunities. In a world where supply chain agility equals competitive advantage, effective planning isn’t just operational—it’s strategic.